- Home

- About us

- Products

- Solutions

- Archive

- News

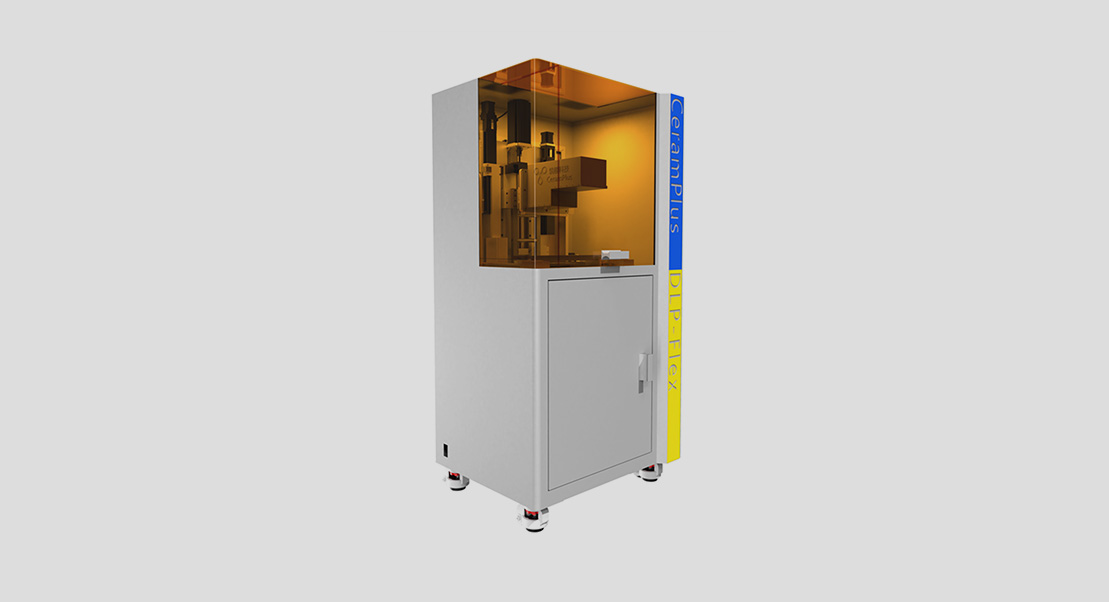

Advanced ceramic 3D printer CeramPlus DLP series

The advanced ceramic 3D printer CeramPlus DLP-Flex is an ideal choice for modern ceramic 3D printing equipment.

Product advantages:

1. One machine with multiple functions can realize different printing precision requirements of different ceramic products and meet the wide range of size requirements of customers.

2. Choose 385nm wavelength for LED light source to make ceramic resin curing faster and more complete.

3. The sinking design ensures 24 hours continuous and reliable printing in industrial grade, which is suitable for more large-size products.

4. The low-viscosity ceramic printing paste matched with the printer can achieve a service life of up to 180 days.

5. There are many types of low-viscosity ceramic materials matching the printer, and customized product design and preparation can be provided according to customer needs.

DLP-Flex technical parameters

category Sunken DLP ceramic printer Projection resolution Single unit can achieve single pixel resolution of 30µm, 50µm, 70µm and 100µm Print format 57.6×32.4mm (30µm), 96.0×54mm (50µm),134.4×75.6mm (70µm), 192.0×108.0mm (100µm), Printing speed >100 Layer/hour Printing layer thickness 30~100μm Adjustable UV wavelength 385nm Use environment 25℃~40℃ Dimensions 750x600x1420 mm Total Weight About 150 kg Operating system Windows 7/10, Slicing function included in the printing software Applicable file format .stl, .slc, .cws Applicable materials Ceramic photosensitive slurry such as zirconia, alumina, silica and hydroxyapatite *This parameter is related to the printing material used, and the single-layer exposure time will vary with the printing parameters.

#The precise range of this parameter is related to the type of printing material, and the printer can achieve continuous adjustment of the entire range.

- Products