- Home

- About us

- Products

- Solutions

- Archive

- News

Material

In order to allow the industry to share the technological advancements brought about by 3D printing technology, Rao Ji Technology provides customers with customized development of 3D printing materials. Customers can provide or designate specific types of ceramic raw materials from suppliers, including but not limited to: zirconia, silicon oxide, alumina, silicon carbide, silicon nitride, hydroxyapatite, etc., and propose the desired performance indicators. Such as: sintered density, 3-point bending strength, etc. Rao Ji can design and manufacture commercial 3D printing materials that can be used on a large scale based on this customized demand.

-

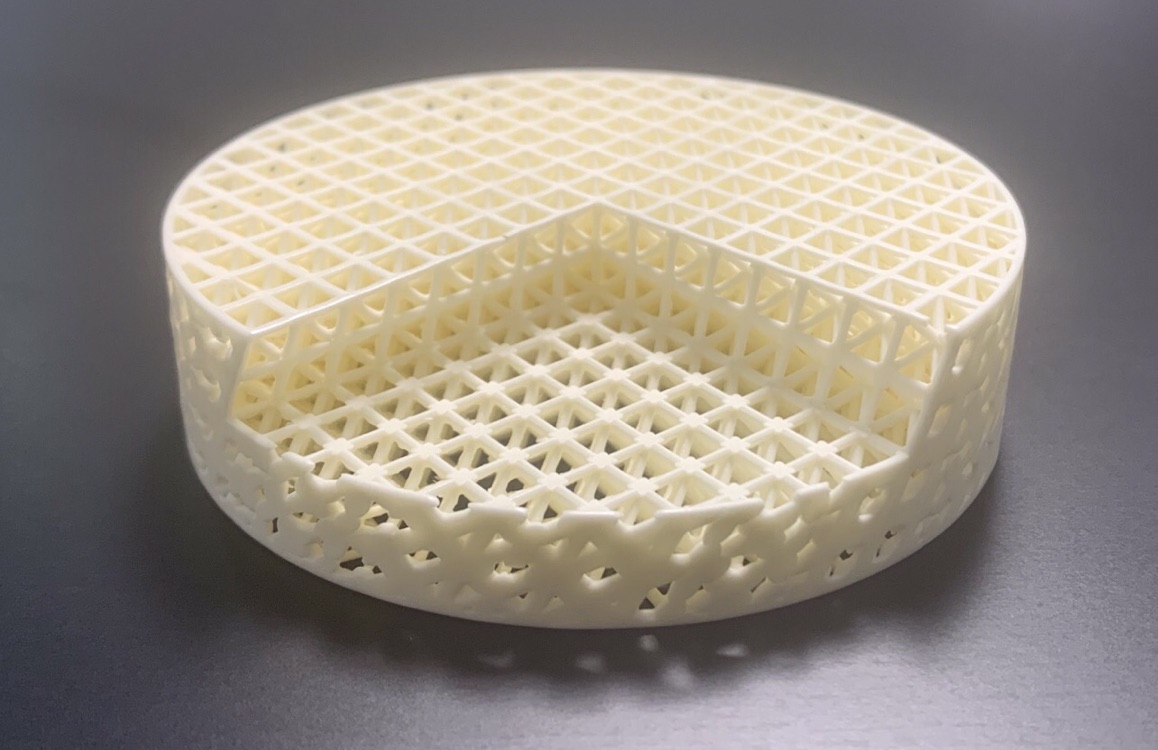

![3D printing alumina (Al2O3) materials]() 3D printing alumina (Al2O3) materialsKnow moreThe alumina 3D printing material produced by Rao Ji is based on 99.6% alumina, and it can also accept customized services for printing materials of other purity alumina.

3D printing alumina (Al2O3) materialsKnow moreThe alumina 3D printing material produced by Rao Ji is based on 99.6% alumina, and it can also accept customized services for printing materials of other purity alumina. -

![3D printing zirconia (ZrO2) material]() 3D printing zirconia (ZrO2) materialKnow moreThe zirconia 3D printing materials produced by Rao Ji include medical series and non-medical series to meet the different needs of the market. All zirconia printing materials can provide the market with material properties comparable to traditional isostatic pressing processes.

3D printing zirconia (ZrO2) materialKnow moreThe zirconia 3D printing materials produced by Rao Ji include medical series and non-medical series to meet the different needs of the market. All zirconia printing materials can provide the market with material properties comparable to traditional isostatic pressing processes. -

![3D printing silicon dioxide (SiO2) material]() 3D printing silicon dioxide (SiO2) materialKnow moreThe silica 3D printing material produced by Rao Ji cooperates with our patented 3D printing technology to produce components with precise dimensions, good surface finish, complex internal structure and surface shape, such as casting cores, which are high-end precision casting industry The weapon of manufacture.

3D printing silicon dioxide (SiO2) materialKnow moreThe silica 3D printing material produced by Rao Ji cooperates with our patented 3D printing technology to produce components with precise dimensions, good surface finish, complex internal structure and surface shape, such as casting cores, which are high-end precision casting industry The weapon of manufacture. -

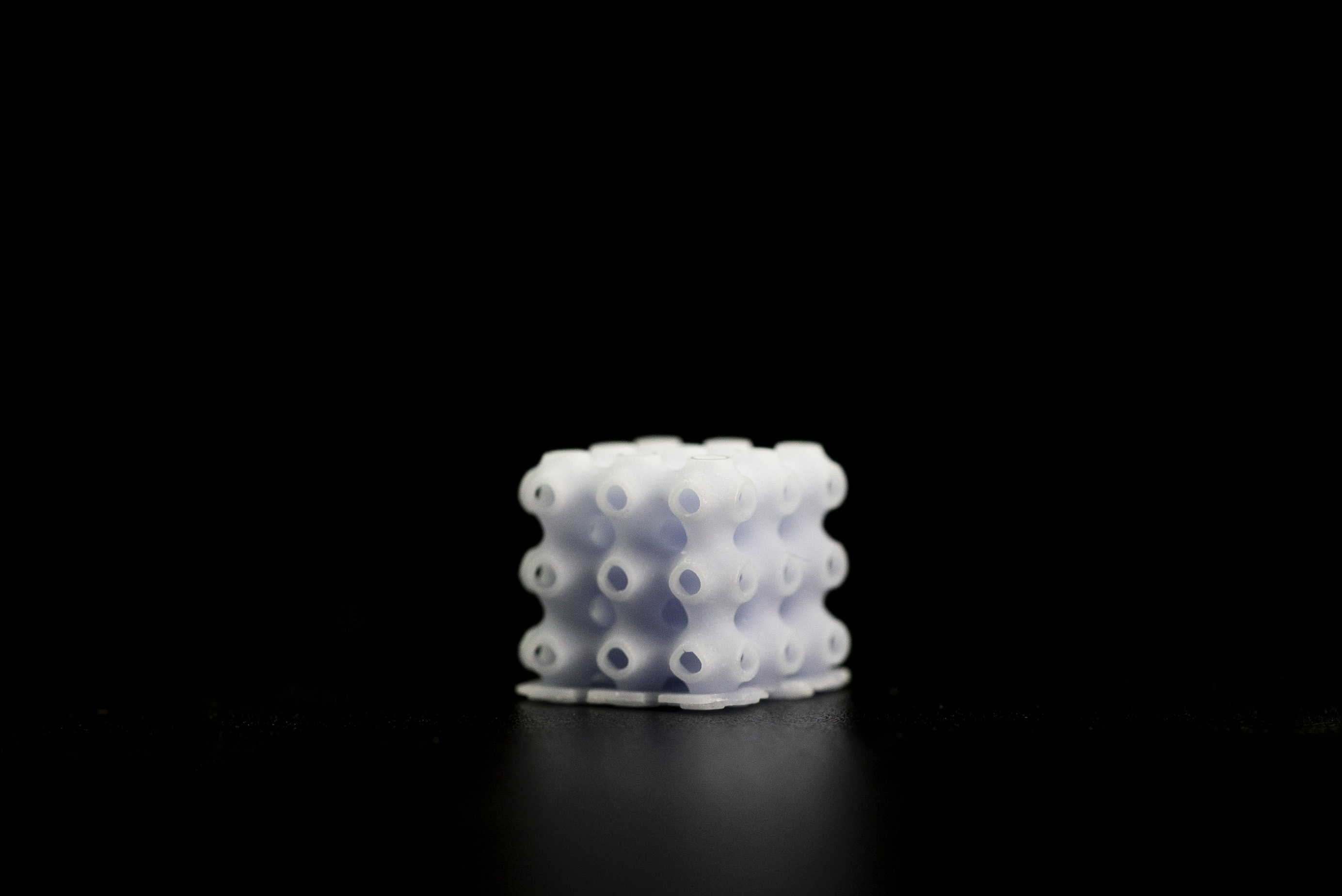

![Hydroxyapatite]() HydroxyapatiteKnow moreHydroxyapatite has attracted more and more attention in the medical and industrial fields. Rao Ji Technology's self-developed HAP high-strength hydroxyapatite 3D printing paste has good mechanical properties and surface finish after printing, forming and sintering. It is an ideal choice for applicable scenarios.

HydroxyapatiteKnow moreHydroxyapatite has attracted more and more attention in the medical and industrial fields. Rao Ji Technology's self-developed HAP high-strength hydroxyapatite 3D printing paste has good mechanical properties and surface finish after printing, forming and sintering. It is an ideal choice for applicable scenarios.

- Products