- Home

- About us

- Products

- Solutions

- Archive

- News

We Are CeramPlus

CeramPlus focuses on material innovation as the core driving force to provide for the consumers advanced and comprehensive 3D printing schemes of elaborate ceramic products with the combination of industrial printing devices.

SOLUTIONS

We own the world’s leading R & D technology of the ceramic materials, which has been supplying various application to more and more industrial scenes via 3D Printing, thus demonstrating its potentialities hidden in modern industry.

-

![Material]() MaterialWe provide customers with 3D printing material service, including, but not limited to, zirconia, silicon oxide, alumina, silicon carbide, silicon nitride, hydroxyapatite, etc. Based on this can be designed and manufactured the 3D printing materials which are commercialised and accessible in large-scale application.

MaterialWe provide customers with 3D printing material service, including, but not limited to, zirconia, silicon oxide, alumina, silicon carbide, silicon nitride, hydroxyapatite, etc. Based on this can be designed and manufactured the 3D printing materials which are commercialised and accessible in large-scale application. -

![Device]() DeviceThe self-developed ceramic 3D printer owns complete independent intellectual property rights in its hardware, software, material adaptation and material microstructure, which can give great freedom to industrial design.

DeviceThe self-developed ceramic 3D printer owns complete independent intellectual property rights in its hardware, software, material adaptation and material microstructure, which can give great freedom to industrial design. -

![Design]() DesignCustomized product design meets all kinds of specific needs on the components and breaks through the technical barrier of the fine structure which can not be achieved via traditional manufacturing methods.

DesignCustomized product design meets all kinds of specific needs on the components and breaks through the technical barrier of the fine structure which can not be achieved via traditional manufacturing methods. -

![Craft]() CraftScientific and rigorous production process not only meets the need of structure, size and surface finish, but also it strictly corresponds to the standard of mechanical properties after the process of design, shaping and manufacture of the components.

CraftScientific and rigorous production process not only meets the need of structure, size and surface finish, but also it strictly corresponds to the standard of mechanical properties after the process of design, shaping and manufacture of the components. -

![Service]() ServiceThe service consciousness of modern industry is embodied all along, which enables us to provide products and service of high quality constantly for the customers.

ServiceThe service consciousness of modern industry is embodied all along, which enables us to provide products and service of high quality constantly for the customers.

APPLICATION SCENARIO

-

![]() Precision filter elementThe ceramic filter element customized by 3D printing technology can effectively control the filtration speed, has powerful adsorption performance for impurities, and does not produce any impurities during the filtration process. It helps enterprises filter and refine high-purity liquid metal or other material when producing specific devices, so that the performance of final solid-state molding device can meet the high standards of hardness, heat resistance, etc.

Precision filter elementThe ceramic filter element customized by 3D printing technology can effectively control the filtration speed, has powerful adsorption performance for impurities, and does not produce any impurities during the filtration process. It helps enterprises filter and refine high-purity liquid metal or other material when producing specific devices, so that the performance of final solid-state molding device can meet the high standards of hardness, heat resistance, etc. -

![]() Casting coresCeramPlus can customize components with complex structure according to specific casting process requirements. It has excellent surface finishment so that it can form perfect cavity structure. With the characteristics of low thermal expansion coefficient and solubility, The self-developed silicon oxide ceramic core is the perfect production material for the casting core.

Casting coresCeramPlus can customize components with complex structure according to specific casting process requirements. It has excellent surface finishment so that it can form perfect cavity structure. With the characteristics of low thermal expansion coefficient and solubility, The self-developed silicon oxide ceramic core is the perfect production material for the casting core. -

![]() Dental CrownVia 3D printing the efficiency of diagnosis and treatment on dental patients can be improved greatly. After the doctor scanning the medical image of the teeth and gums of the patients, 3D printing data can be achieved. After the processes of Sintering, dyeing, glazing, grinding, etc, the high quality product of dental crown can be attained. The printing is far more efficient than the traditional cutting technology. Moreover, it’s easy to operate so as to diminish the time and human cost.

Dental CrownVia 3D printing the efficiency of diagnosis and treatment on dental patients can be improved greatly. After the doctor scanning the medical image of the teeth and gums of the patients, 3D printing data can be achieved. After the processes of Sintering, dyeing, glazing, grinding, etc, the high quality product of dental crown can be attained. The printing is far more efficient than the traditional cutting technology. Moreover, it’s easy to operate so as to diminish the time and human cost. -

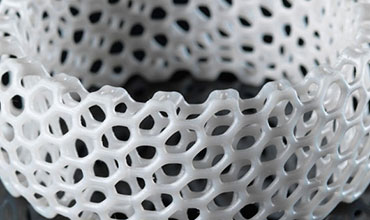

![]() ArtworkThe 3D printing technology of CeramPlus can allow the printing and forming of complex structure artworks to turn designers' instant inspiration and creativity into reality. The self-developed ceramic 3D printing slurry and ceramic 3D printing equipment can make the surface finishment of the work achieve perfect effect, and enhance the texture of the work in the details.

ArtworkThe 3D printing technology of CeramPlus can allow the printing and forming of complex structure artworks to turn designers' instant inspiration and creativity into reality. The self-developed ceramic 3D printing slurry and ceramic 3D printing equipment can make the surface finishment of the work achieve perfect effect, and enhance the texture of the work in the details.

INDUSTRIES

![Aerospace]() AerospaceAerospace plays a leading role in industrial technology. The 3D Printing technology of CeramPlus demonstrates its advantage of application in this area. Through the cooperation with partners, remarkable service benefits can be achieved. The areas of advantage include:

AerospaceAerospace plays a leading role in industrial technology. The 3D Printing technology of CeramPlus demonstrates its advantage of application in this area. Through the cooperation with partners, remarkable service benefits can be achieved. The areas of advantage include:

1.The breakthrough in material science and the application makes it possible to apply more ceramic opponents to aerospace, including weight-reduction of the structure, preparation of advanced casting tools and complicated core, etc.

2. Ceramization and production of the components aimed at the maintenance of old instruments.

3. Scientific research cooperation in material science.

![Manufacturing]() Manufacturing3D printing technology has been constantly getting mature, and the application field of advanced ceramic materials has also been constantly breaking through. All kinds of ceramic components with complicated structure has been increasingly applied to industrial scenes. The application of lightweight ceramic structural components is the trend of modern industry.

Manufacturing3D printing technology has been constantly getting mature, and the application field of advanced ceramic materials has also been constantly breaking through. All kinds of ceramic components with complicated structure has been increasingly applied to industrial scenes. The application of lightweight ceramic structural components is the trend of modern industry.![Oral cavity]() Oral cavityThe zirconia crowns printed by Rao Ji Technology have mechanical properties comparable to those of porcelain cake-based crowns processed by traditional CNC cutting. The surface finish is better than traditional processes. The production efficiency of a single device is 7 times that of traditional processes, greatly improving all-ceramic teeth. Crown production efficiency.

Oral cavityThe zirconia crowns printed by Rao Ji Technology have mechanical properties comparable to those of porcelain cake-based crowns processed by traditional CNC cutting. The surface finish is better than traditional processes. The production efficiency of a single device is 7 times that of traditional processes, greatly improving all-ceramic teeth. Crown production efficiency.![Arts]() ArtsIn the art goods industry, the traditional process has the disadvantages of long manufacturing cycle, high manufacturing cost, intricate process, poor precision, insufficient innovative design. 3D printing has brought technological breakthroughs for these industries such as the change of production process, customized service and more complicated design, which will push the development of the whole industry into customization, unique design and digital manufacturing. Raoji technology's ceramic 3D printing technology makes ceramic artwork goods break through the traditional limitations and ceramic art more expressive and colorful.

ArtsIn the art goods industry, the traditional process has the disadvantages of long manufacturing cycle, high manufacturing cost, intricate process, poor precision, insufficient innovative design. 3D printing has brought technological breakthroughs for these industries such as the change of production process, customized service and more complicated design, which will push the development of the whole industry into customization, unique design and digital manufacturing. Raoji technology's ceramic 3D printing technology makes ceramic artwork goods break through the traditional limitations and ceramic art more expressive and colorful. - Products